Up

Contents

Quote Me!

Chinese Page

Arabic Page

Japan

| |

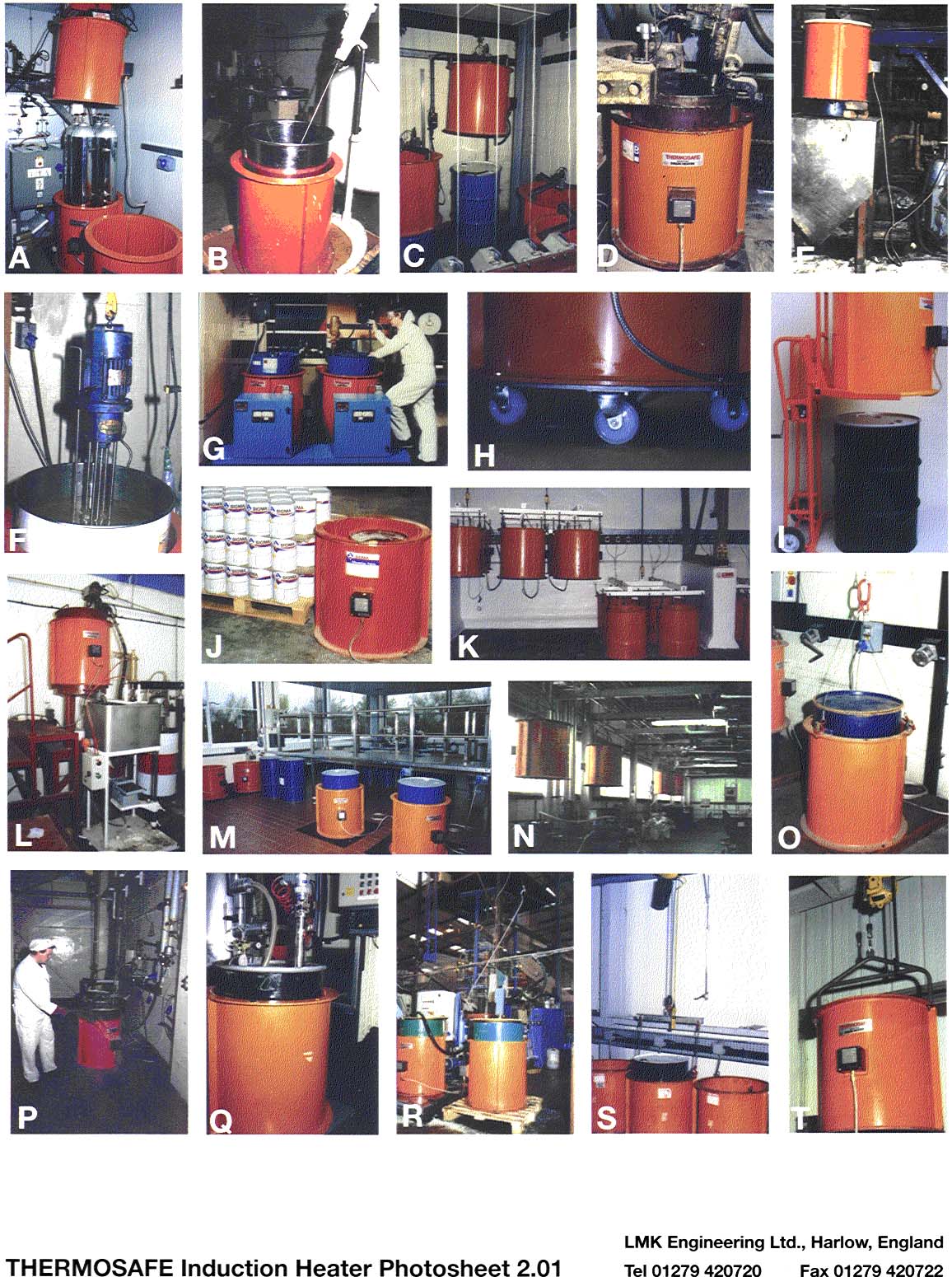

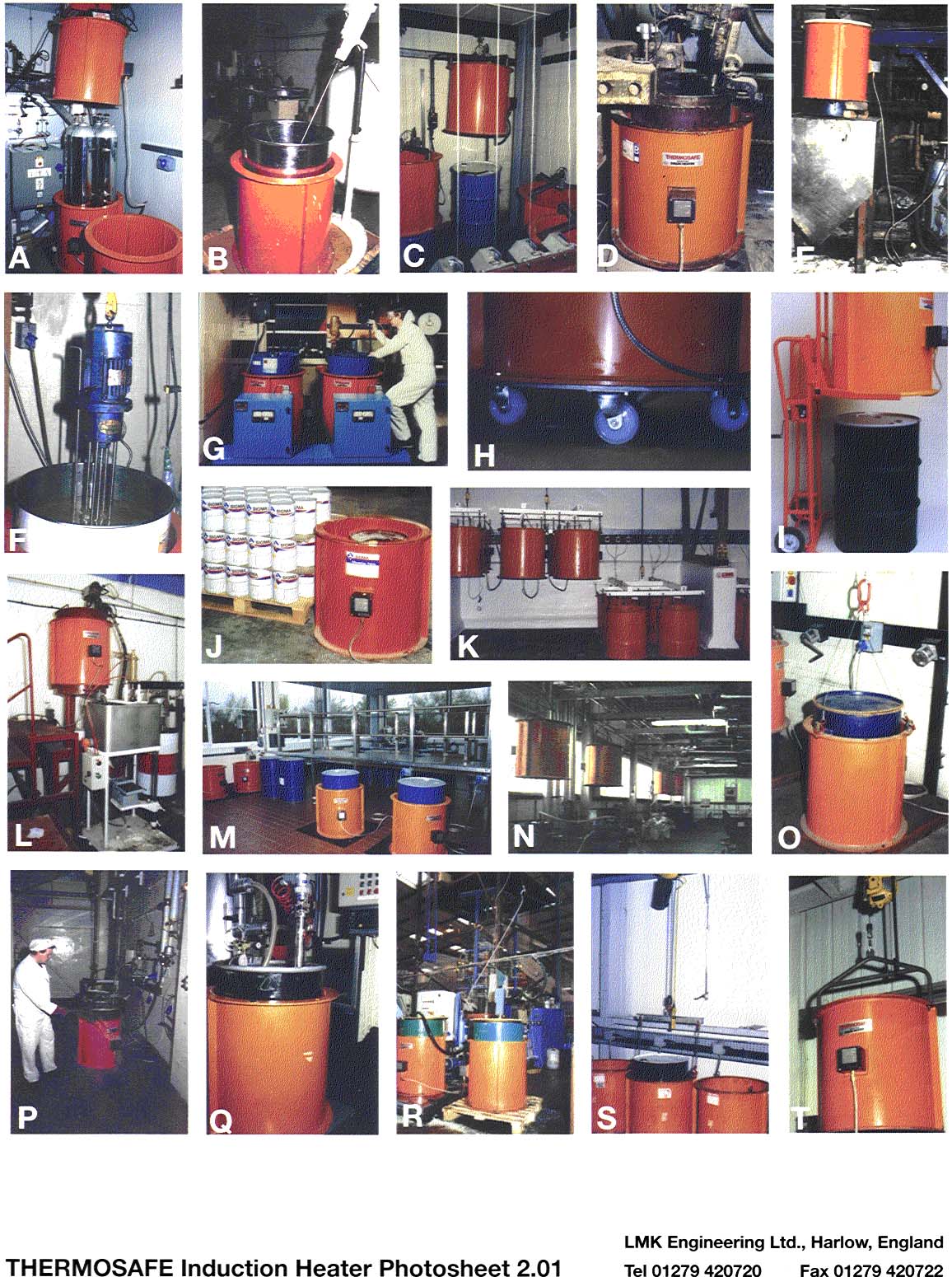

Application Note Photographs

The complete photo set may take about one minute to load in full.

Descriptions by code letter:

- Even heating of gas cylinders to dry very high levels of purity. Other gas

bottle applications include driving-off acetone from spent acetylene

cylinders.

- Plant producing a wide range of cosmetic and toiletry products. The

depicted process involves adding a range of fragrances to shaving cream.

- Very confined space leading to use of manual safety winches.

- Non "drum" applications, heating a process vessel in a hazardous

location. The company manufactured wall sections for the Channel Tunnel

between England and France.

- Supplier of bitumens for road-surfacing and roofing. Shown emptying

heavily filled bitumen into an oil heated process vessel below.

- Shoe manufacturer - demonstrating easy access to drum whilst heating.

- Aerospace - mobile pumping stations for Ciba-Gigy epoxy resin, used in the

manufacture of aircraft propellers.

- Drums of glycerin mounted on dollies to enable quick removal/access to a

pumping head on the "Jaffa-cake" production line.

- LMK stacker for Thermosafe

- Paint manufacturer - heating 110 litre drums.

- Honey farm - frames allow application of banks of up to six heaters at a

time to be applied.

- Non "drum" application, heating special process vessel.

- Pharmaceutical manufacturer - six heaters replaced a drum oven heating

sorbitol, the main constituent of liquid medicines. The heaters sit on

rubber mats on a tiled floor, allowing for hosing down even when in

use.

- Luboil blending - heaters are kept overhead when not in use (replaced

steam oven, allowing shut-down of boiler during the summer months.) See also

"T".

- Heating bitumen for injecting into undersea cables.

- Food plant - heating beef fat oleo.

- Food plant - providing a monitored flow of lecithin at constant

temperature to the adjacent plant manufacturing a butter-type cooking oil

used in bakeries.

- Plastics manufacturer - 2 heaters by the side of each plant making

continuous plastic film. 24 hour operation, with 1 drum feeding, the other

as back-up.

- Luboil blending - 18 drums in one line along wall. See Esso Project Report,

Eastern Electricity award winning case history. Became the model for this

major oil company's luboil plants around the world.

- Luboil blending - close-up of "N" above.

|